Real temperature-induced stress calculation of new secondary concrete containments, as well as confirming the temperature resistance of coatings, is a regular challenge and limits the potentially available solutions.

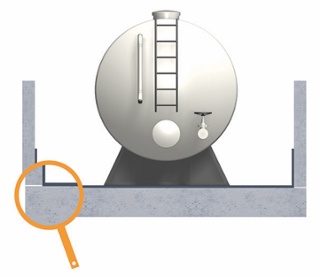

From production to transportation and storage, hazardous goods need to be well protected at all times. The ground water protection law even stipulates that facilities handling water-polluting substances must use a double protective layer for those goods. This involves a primary barrier in the form of a containment safely enclosing the hazardous material, and a further retaining system known as the secondary barrier. This can be a collecting basin or a coated surface that ensures that the hazardous material is safely retained in the event of spillage to protect the surface and groundwater from contamination.

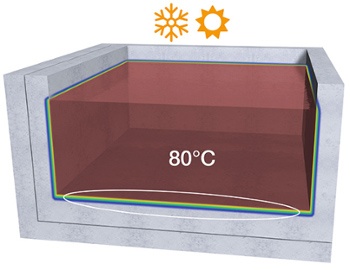

The secondary barrier is often made of concrete and additional resistance coatings are occasionally applied to the concrete. The problem is that hot liquids, for example, can cause cracks in the concrete and the additional coating systems have only been tested to withstand certain temperatures. The hotter the hazardous material that needs to be retained, the thicker the concrete secondary barrier needs to be to prevent cracks and ensure the necessary tightness. As the temperature rises, the required component thickness and volume of reinforcement increase very quickly. The result is high cost and considerable effort.

New calculation tool to avoid expensive special solutions

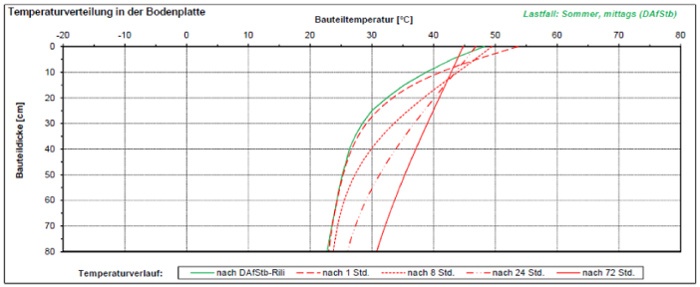

In collaboration with the University of Science Kaiserslautern, a team within Civil Engineering has developed a calculation tool that allows to design thinner concrete structures, with less reinforcement and to use usual coating solutions even in high temperature storage areas. The Excel-based program calculates the actual temperature profile of each hazardous liquid spilled on the concrete surfaces.

The tool takes into account the mass of the concrete and the heat transfer between the liquid and the concrete. These effective temperaturesare usually significantly lower than the storage temperatures of the liquids that have been used in calculations up to now.

The benefits of this can be enormous. When pure concrete structures are used as a sealing surface, the lower base temperature results in smaller dimensions and reinforcement quantities.

The lower base temperature calculated in the tool avoids overdesign and enables the most economic coating solution to be used. Overall, the consequence is that expensive special solutions and unnecessarily thick secondary barriers will need to be used far less often. Instead, it is possible to use simple standard coatings such as the construction chemical product line from Master Builders Solutions®.

The new Excel tool introduces effective temperatures and thus allows smaller concrete dimensions, less reinforcement and the use of simple coating systems instead of expensive special solutions.

Get in touch with one of our experts to learn more about this money-saving calculation tool.