Highly flowable concretes have many advantages: they are easier to pump, lay and compact than conventional concretes with a stiff, plastic consistency. Nevertheless, highly flowable concrete poses a number of challenges: the high degree of flowability results in a segregation tendency which has a negative impact on strength and durability. At the Admixtures Symposium held by the Concrete Society in London at the end of September, Master Builders Solutions expert Oliver Mazanec discussed the causes of this phenomenon and presented stabilizers to prevent it.

When buildings break records, concrete is a key factor. Whether we are talking about the Burj Khalifa in Dubai, the tallest building in the world, the 601-metre-tall Makkah Royal Clock Tower in Saudi Arabia, the 541-metre-tall One World Trade Center in the USA, or the Kingdom Tower in Saudi Arabia currently under construction, which will probably reach 1000 m – none of these impressive buildings could have been realized without the right concrete

High demands mean additional challenges

The challenges faced by the material are extremely steep and very special. Among other things, the concrete must be extremely strong, self-compacting and allow pumping over long distances. Concrete with these properties is highly flowable and such concrete tends to segregate. The consequences include reduced strength and marbled surfaces that release sand, as well as higher porosity and reduced durability. These challenges and the possibilities of tackling them were the topic of the presentation made by Oliver Mazanec, an expert in concrete and concrete admixtures from Master Builders Solutions, at the Admixtures Symposium held by the Concrete Society in London. Stabilizers are the key to preventing the segregation of flowable concrete as well as “bleeding”, the unwanted release of water from the mixture, according to Mazanec.

Flowable when moving, stable when stationary

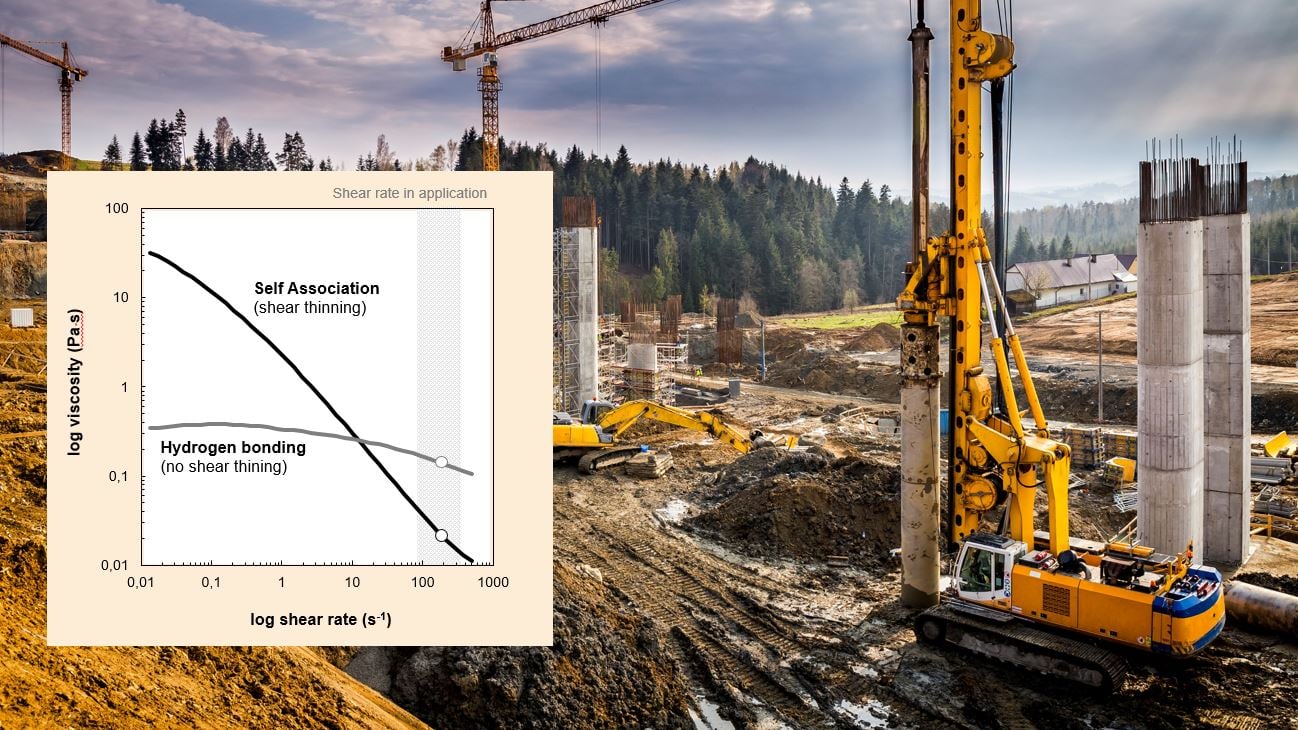

The requirements differ considerably depending on the application of the concrete. If the material is pumped over long distances to the point of use, as in the case of skyscrapers, structural viscosity plays a key role. In this case, it is beneficial if the concrete remains as flowable as possible during pumping but then becomes as stable as possible following laying. In other words, a high shear rate must result in low viscosity and the viscosity should ideally be increased immediately when the shear rate is reduced. The result would be a sturdy concrete with a stable distribution of its constituents. These properties can be controlled using a shear thinning admixture such as MasterMatrix SCC 210, a product newly developed by Master Builders Solutions that is especially well-suited for highly flowable concretes. It was presented to the building sector by Mazanec for the first time at the symposium.

No bleeding under pressure

Concretes cast in tall, narrow moulds, as in retaining walls or drilled piling, pose fundamentally different challenges. Here too, the concrete must be highly flowable and extremely strong. However, it is the height that presents a challenge. When the concrete is laid, the material at the bottom of the formwork or drilled pile is exposed to extremely high pressure. As a result, the concrete “bleeds”; water escapes from the fresh concrete, compromising its strength and durability after curing. In this case, it is recommended to use a stabilizer such as MasterMatrix SDC 100 from Master Builders Solutions: in contrast to shear thinning concrete admixtures, this special product ensures high viscosity under high shear forces, thus preventing segregation.

If you have any inquiries about highly flowable concrete, feel free to contact Oliver for assistance and individual advice.

Oliver Mazanec