Concrete with a large share of cement replacement materials may be more environmentally compatible and often also more durable than conventional concrete but it is not necessarily easy to produce and process. This is why the concrete producer opted for a solution from Master Builders Solutions for a new building of SRF, the Swiss radio and television organization. The innovative superplasticizer MasterEase eliminates all the disadvantages.

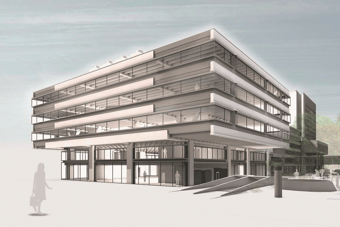

Fast, flexible, and always up to date – this is how radio and TV stations work. The conditions must be right: in addition to media professionals in front of and behind cameras and microphones, this applies especially to the complex technology that makes brilliant images and sounds possible. The new complex constructed for SRF at its Zurich location is designed on this basis but also meets the highest construction standards.

Flexible planning for a modern media company

The construction of the new central technology building as well as a news and sports center at the SRF location in the Zurich district of Leutschenbach is part of the planned medium and long-term development of the organization, which focuses on existing properties and on optimizing the costs of land and building. The buildings are of modular design, allowing flexible adaptation to changing requirements. In addition, the complex was planned to ensure compliance with modern energy efficiency standards. The new technology center lays the foundation for efficient, sustainable energy supplies to the entire facility.

The construction of the new central technology building as well as a news and sports center at the SRF location in the Zurich district of Leutschenbach is part of the planned medium and long-term development of the organization, which focuses on existing properties and on optimizing the costs of land and building. The buildings are of modular design, allowing flexible adaptation to changing requirements. In addition, the complex was planned to ensure compliance with modern energy efficiency standards. The new technology center lays the foundation for efficient, sustainable energy supplies to the entire facility.

Durable, resilient, environmentally compatible concrete

For the implementation of the project, the architects had specified a concrete with class CEM III/B blast furnace cement. The large share of metallurgical sand in the cement not only means that the concrete has an especially light color. The concrete is also more resistant to a variety of chemical attacks and develops lower heat of hydration, resulting in a reduced cracking tendency, which also makes for a more durable building. In addition, blast furnace cement is more environmentally compatible than conventional Portland cement. Less energy is required for production and carbon dioxide emissions are therefore also reduced.

Environmentally compatible concrete – difficult to use

Despite all their advantages, concretes mixed using these cement also pose challenges. They are comparatively sticky and less easy to process – especially during pumping, as the sticky consistency of the concrete often causes considerable problems. This was the stage reached by Toggenburger AG, the concrete supplier for the SRF project, after a number of preliminary tests, which is why the supplier contacted the experts from Master Builders Solutions. The question was whether the Master Builders Solutions range included a product that could be used to master this challenge.

The experts did not have to think about this problem for very long. This was clearly a case for MasterEase. Tests with the innovative superplasticizer led to outstanding results during the processing and pumping of the concrete.

MasterEase: innovative superplasticizer for improved rheology

MasterEase is an innovative admixture to improve the flowing properties, of the rheology, of concrete. Especially concretes with a large share of cement replacement materials, such as the metallurgical sand in this concrete, are often highly viscous and sticky, which can present problems for the installation, compaction, smoothing, and pumping of the material. In addition, mixing takes longer and the cured concrete often has surface defects. Admixtures from the MasterEase series now allow the production of concrete with plastic viscosity reduced by up to 30 percent at the same time as maintaining high resistance to de-mixing. The new technology, therefore, allows more environmentally compatible production and considerably more time-efficient concreting at the same time as reducing stress on the equipment used and ensuring concrete surfaces of outstandingly high quality.

Two types of concrete with MasterEase

Two different types of concrete were specified for casting a complex ceiling structure – coffered ceilings with a grid structure – for the basement and ground floor. These were self-compacting concrete for the pillars, which were to be integrated into the composite structure as seamlessly as possible, and pumped concrete for the surfaces. Both concretes were optimized using MasterEase.

For the self-compacting concrete, the viscosity-modifying admixture MasterMatrix was also used. After the concrete had been properly treated and allowed to cure until it could be walked on, the ceiling areas were initially prestressed and then overstressed after four weeks in accordance with the technical specification.

The result was a light concrete surface that was free from pores. Visible concrete walls, staircases, and facade elements were produced using the same concretes. In addition, concrete admixtures from Master Builders Solutions were used in the prefabricated concrete elements for the two ceilings.

Any questions? Feel free to reach out to Oliver and browse through our informative brochure about MasterEase.

Oliver Mazanec