Placing concrete in hot weather brings about many challenges that can have long-term implications if not dealt with correctly. The temperature of the fresh concrete and the site conditions have a decisive influence on the properties of the fresh concrete and how it can be processed by placing, finishing and curing, and ultimately on the performance, quality and durability of the finished structure. In addition to sensible precautionary measures on site, the use of concrete admixtures is one of the most effective ways to effortlessly achieve the desired concrete quality even under warmer conditions. In our quest for perfect concrete quality we have devised a list of the seven essential factors to take into account when pouring concrete on hot summer days:

1. Workability changes in hot weather

If the temperature of the constituent materials of the concrete is already high, the temperature of the fresh concrete will also be elevated, which will accelerate setting times and the strength development of the concrete. This will result in shortened workability times. In the case of ready-mix concrete, transport in a mixer truck in summer poses a major challenge for maintaining workability with the risk that the concrete will not have the specified consistency when it arrives at the construction site. This can have a negative impact on placement, finishing, and compaction and ultimately on the quality of the hardened concrete. Improving workability by simply adding more water will lower the strength and durability of the final product and cannot be recommended.

2. Strength development is different

Similar to heat treatment, the chemical reaction of cement hydration at high temperatures leads to the formation of calcium-silicate hydrates with different microstructures: the crystals grow faster and coarser, their assembly is less homogeneous and the packing density is lower. The acceleration leads to higher early strengths but at the same time will might result in a loss of final strength and durability.

Excessive water evaporation at the surface prevents complete hydration of the concrete, resulting in a lower-density microstructure characterized by lower strength. In addition to this tendency to dust, reduced durability is the expected outcome with low penetration resistance to external influences such as water and pollutants – including CO2 and chlorides – which significantly reduces the service life expectancy of concrete structures containing reinforcing steel.

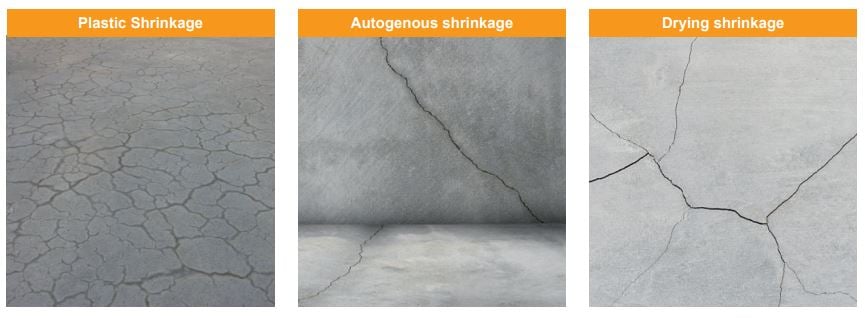

3. The risk of shrinkage increases

If, after placement, the surface of the concrete dries too fast, the risk of shrinkage cracking appears because sufficient tensile strengths have not yet been achieved. The evaporated water quantity can be predicted depending on the most important influencing variables: relative humidity, ventilation, and concrete temperature. The addition of more water for consistency compensation will further increase the tendency to shrink.

When temperatures are above 25°C, or there is strong air movement, additional measures become a necessity to reliably achieve the required quality of concrete.

Remember: If the storage temperature of the concrete constituent materials is too high, it will probably have a negative effect on the strength and durability of the final concrete.

4. Getting the concrete mix right matters

One workaround is the use of cements such as CEM III which are characterized by low hydration heat development in the initial phase. The use of low-clinker cement will also compensate for the disadvantages associated with hot climatic conditions and will have a positive effect on CO2 emissions, the importance of which in relation to sustainability goals is quite well-known.

The use of admixtures which is an effective way to mitigate the impact of hot climatic conditions will be discussed in point seven.

5. Keeping the production and placement of concrete cool

Prevention begins with the storage of constituent materials. Make sure that the aggregates are correctly stored, for example by covering the aggregate with insulating mats to keep temperatures lower than those of the surrounding area. Evaporative cooling by spraying the aggregate with fine water vapor is a further possibility but remember to take the increased moisture content of the aggregates into account when determining the water content of the mix! While the cooling of aggregates which make up the majority of concrete mix ingredients has the greatest effect, liquid nitrogen cooling of raw materials or fresh concrete, in general, can also be considered.

Other preventative measures may include concrete production with cool well water or flake ice. When using flake ice, be aware that it should be considered part of the total mixing water required to achieve the desired water/cement ratio. You should also keep the reinforcement steel cool by providing shade or spraying them with water. Finally, the substrate can also be pre-wetted before concreting.

6. Concrete processing must suit the conditions

Summer conditions will dictate how you work in order to minimize the chance of compromising the long-term performance of your concrete. Avoid concreting in direct sunlight as far as possible by creating shade. It is sensible to postpone concreting work to cooler times of the day, typically early morning, evening, or night. Avoid long transport and layover times and ensure rapid concrete processing by having enough personnel and equipment available where and when needed. It goes without saying that you should not place stiffened concrete.

7. Admixtures can help you overcome the obstacles

The construction industry faces tight-time schedules and with the added complication of hot-weather working, projects can be put at a disadvantage. One technical solution is to use admixtures to mitigate the uncertainty of hot weather conditions. The main benefits of using admixtures include:

- Reduced water demand

- Hydration control

- Improved workability

- Curing control

- Increased compressive strength

- Durability

Our newly developed generation of MasterEase products, for example, make it possible to robustly maintain workability over a long period of time under all climatic conditions and when used with low-clinker cements, with low heat generation.

MasterSure, on the other hand, was developed using slump retention technology that will help concrete retain its workability at higher temperatures. Here, concrete delivery and consistency of performance are achieved as the admixture maintains cement dispersion in fresh concrete, so that workability is maintained over longer periods without affecting setting time or early strength development.

MasterSet influences the reaction of the C3A phase of the cement. This delays cement hydration and dampens the heat caused by hydration. As a result, concrete can be easily processed and placed more flexibly over a longer time period. The retarding effect also increases the final strength of the concrete and reduces creepage and shrinkage.

In particular the use of curing agents such as MasterKure is highly recommended when producing concrete floors as they offset the negative effects of high evaporation rates that can otherwise significantly reduce the quality of the finished pavement surface.

MasterKure application on construction site after placing the concrete

/in%20USE/JS106-374_INTERPOLIERT_RZ_ll.jpg)

/in%20USE/Bettocure_C_1_RZ.jpg)

Last but not least, shrinkage reducers such as MasterLife SRA protect the concrete from the effects of shrinkage and the resulting cracking.

Today, there is a wide range of concrete admixtures available to enable the reliable adaption of concrete mixes to climatic conditions and individual project requirements. Furthermore, we must take the temperature-mitigating effects of concrete admixtures into account if we are to avoid the uncontrolled addition of water to mixes on site and prevent a significant reduction in concrete quality, compressive strength, and durability!

For more information about concreting in summer or for individual advice on mix design and admixture selection, please contact our expert Nicoletta Zeminian, Customer Segment Manager Ready-Mix & Site-Mix Europe.

Discover more about concrete placement during the winter season with the help of Master X-Seed. Click here for further information.

Nicoletta Zeminian